其工作原理是通过偏心安装的转子与定子固定面相切,两个(或以上)旋片在转子槽内滑动并与定子内壁相接触,将泵腔分为几个可变容积的一种旋转变容积真空泵。

通常,旋片与泵腔之间的间隙用油作为密封,所以旋片真空泵一般是油封式机械真空泵。其工作压强范围为101325-1.33×10-2(Pa),属于低真空泵。它可以单独使用,也可以作为高真空泵或较高真空泵的前级泵。它已广泛地应用于冶金、机械、品质量优良良、电子、化工、轻工、石油及医药等生产和研究部门。

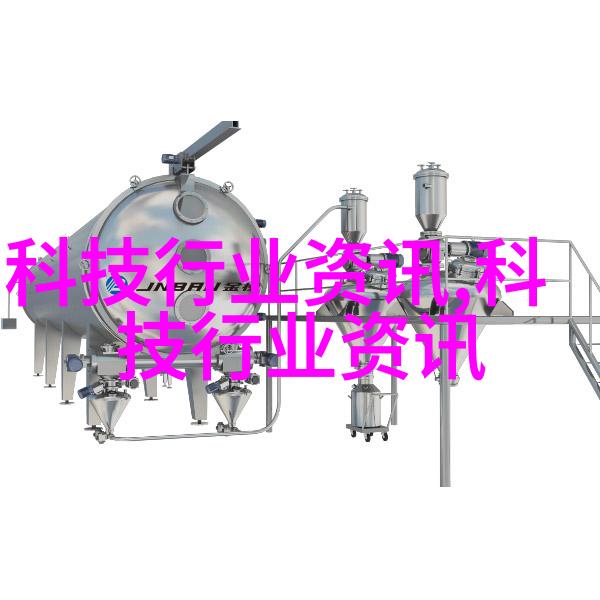

旋片式真空泵结构原理

旋片式真空泵可以抽除密封容器中的干燥气体,若附有气镇装置,还可以抽除确定量的可凝性气体。但它不适于抽除含氧过高的,对金属有腐蚀性的、对泡沫会起化学反应以及含有颗粒尘埃的气体。

旋片式真vacuum技术中基本的true vacuum获得设备之一。旋片多为中小型true vacuum获得设备。一级和二级两种。在结构上将两个单级串联起来,即组成了双级。这时总压缩比由两级来负担,因而提高了优良true vacuum度。

rotary vane pump主要由pump body, rotor, vanes, end plates, and springs组成。在rotary vane pump腔内偏心地安装一个rotor, rotor外圆与pump body内表面相切(二者有很小间隙)。rotating time rely on centrifugal force and spring tension make the vanes stay in contact with the inner wall of the pump cavity.

Rotary Vane Pump's rotary vane brings rotor, pump cavity and two end plates together to form a crescent-shaped space which is divided into three parts: A, B & C. When rotating in one direction towards an arrow mark on the side of the shaft (this is called "forward rotation"), part A expands while part C contracts; when reversing direction ("backward rotation"), part B shrinks as it moves from one end to another.

The true vacuums obtained by this method are used for applications such as electronics manufacturing and scientific research that require high purity gases or low pressure conditions.